Fragola fittings have become a staple within the world of car and overall performance applications, recognized for their high-quality and precision-engineered designs. Fragola Performance Systems has earned its reputation as a pinnacle-tier manufacturer, imparting American-made fittings, hoses, and related components relied on by automotive enthusiasts and specialists alike.

Fragola Performance Systems was founded to produce durable, trustworthy fittings that satisfy the demanding requirements of high-performance vehicles. The organization, originating in the US, has built a robust and revolutionary legacy using years of expertise in fluid and air control technologies. Fragola is a well-known emblem within the automotive industry thanks to its commitment to incredible standards and particular production. Racers, custom automobile developers, and off-avenue fanatics who feel high quality and dependability regularly pick out their fittings.

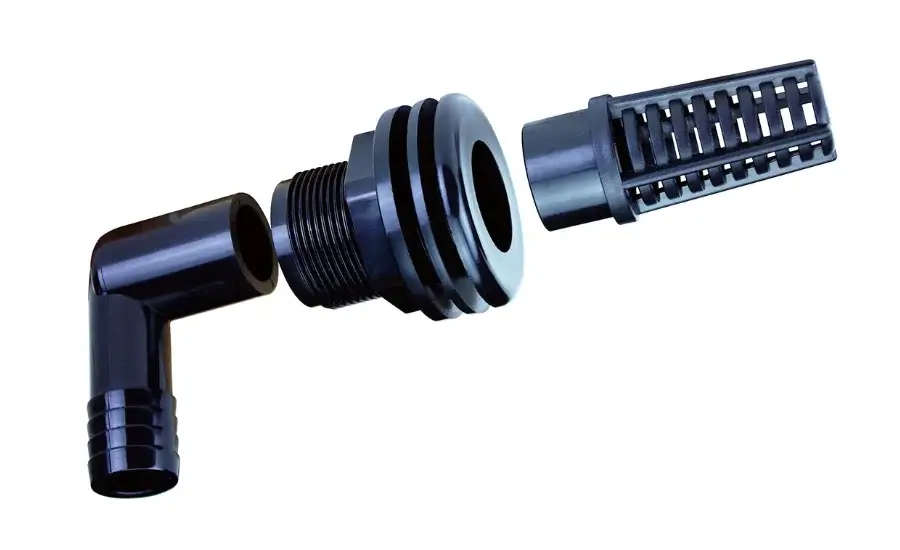

What Are Fragola Fittings?

Fragola fittings are specialty adapters and connections made to make Fluid dynamics in high-performance motors easier. These fittings are essential in automotive structures when fluid, such as coolant, oil, or gasoline, needs to float under pressure without leaking. Fragola fittings, frequently made of anodized aluminium, are corrosion-resistant and designed to handle the harsh conditions of racing and high-performance driving.

Fragola offers an extensive range of fittings to help with various overall performance wishes, from AN (Army-Navy) widespread fittings to custom-designed options for unique automobile configurations. In the context of automotive programs, Fragola fittings are renowned for their compatibility with high-strain systems, supplying secure, durable connections that can resist heat, vibration, and stressful environments.

Fregola’s Commitment to Quality and American Craftsmanship

Fragola Performance Systems’ commitment to manufacturing entirely American-made fittings is one of its defining characteristics. Strict quality control is used throughout manufacturing to guarantee that clients receive components that function flawlessly, even in the most trying circumstances. Fragola takes pride in employing premium materials and cutting-edge technical methods, all carried out at their US facilities. Fragola fittings have become a dependable option for people who require performance and endurance in their vehicles because they emphasise quality and craftsmanship.

Types of Fragola Fittings

Fragola Performance Systems offers fittings created particularly for automobile packages and made to withstand the trials of high-performance settings. Here are some of the most usually used Fragola fittings, which can be designed to satisfy a range of car and motorsport necessities.

AN Fittings

Created to satisfy stringent army requirements, AN (Army-Navy) fittings are usually used fashionable inside the car and aerospace industries. Fittings are renowned for their dependability and sturdiness, particularly in severe temperatures and excessive pressures. They are made to offer a secure, leak-evidence connection in fluid and air structures.

Fittings are perfect for fuel, oil, and coolant lines in performance vehicles because of their standardized dimensions and thread types, which provide broad compatibility across various applications. They are typically made of high-grade aluminium and frequently have an anodized surface that increases strength and prevents corrosion. Fragola’s AN fittings meet these requirements, guaranteeing accurate thread engagement, tight seals, and compatibility with high-performance systems. Because of their design, they are particularly well-liked by car enthusiasts who need reliable, long-lasting connections.

Push Lock Fittings

In many situations, the push lock fittings from Fragola may be installed quickly and securely without clamps or other equipment. These fittings’ distinctive barb-style construction ensures a dependable seal by enabling hoses to “lock” into place with a forceful push. This design reduces the possibility of slippage or leaks during use and saves time during installation.

Push lock fittings are appropriate for coolant applications in automobile settings, air hoses, and fuel lines because they are frequently utilized in lower-pressure fluid systems. In addition to being easy to use, these fittings are designed to continue operating at moderate temperatures and pressures. Push lock fittings from Fragola are made to exact specifications, guaranteeing a strong connection that works well in everyday driving or competitive settings.

PTFE Hose and Fittings

Specialized automotive applications require PTFE (polytetrafluoroethylene) hoses and fittings because of their brilliant resilience to harsh chemical substances and high temperatures. Because PTFE is so resilient and non-reactive, it can resist temperatures and caustic substances that different substances could now be unable to. Because of these qualities, PTFE hoses and fittings are best used in hydraulic programs, oil traces, and gasoline systems where dependability is crucial.

With stainless steel braiding for increased strength and heat resistance, Fragola’s PTFE fittings and hoses are designed to provide optimal performance and longevity. They offer a safe, leak-proof connection that can withstand the rigours of high-performance settings, such as racing and other demanding situations where robustness is essential. Even when exposed to harsh fuels or lubricants, these fittings will hold up over time because of PTFE’s chemical resistance.

Materials and Construction of Fragola Fittings

Fragola fittings are built using top-rate substances, which include stainless steel and anodized aluminium, which are selected for their strength, resilience, and appropriateness for high-performance car settings. Anodized aluminium gives a sturdy, lightweight shape that is stepped forward using an exterior coating that is immune to put on, corrosion and scratches. On the other hand, stainless steel is best for coping with corrosive substances like coolant and fuel because of its super patience and inherent resistance to corrosion.

Fragola employs modern procedures like anodizing, which produces a more complex surface that forestalls rust and oxidation to further protect against environmental impacts. These safeguards guarantee that Fragola fits will remain dependable over time, even under challenging circumstances.

Fragola fittings are designed to prevent leaks with tight seals and precision threading, even in the most demanding applications. They are specially designed to work in environments with high pressures and powerful vibrations. Fragola’s focus on materials, protective coatings, and stringent quality control make them a top choice for automotive professionals and enthusiasts seeking dependability and performance. Their fittings are designed to withstand the demanding environments of off-road use, high-speed driving, and racing.

Benefits of Using Fragola Fittings

Reliability and Safety: Fragola fittings provide a tight, leak-proof seal because they are expertly built and composed of premium materials. This degree of dependability drastically lowers the possibility of fuel, oil, and coolant line leaks, which is essential in high-performance automobile systems. Fragola fittings increase the vehicle’s overall longevity and safety by halting fluid loss and preserving system integrity, giving users comfort and assurance.

Ease of Installation: Fragola fittings are clean to apply and feature a handy design that makes preservation and installation simple. Many fittings have easy threading or short-lock traits that remove the need for specialized gear, making them available to each do-it-yourselfer and professional mechanics.

This simplicity of use guarantees a secure fit every time, saving time and lowering the possibility of installation problems.

Customization Options: Fragola’s extensive selection of fittings in various sizes, shapes, and angles makes finding the ideal fit for any vehicle job simple. Thanks to these customization options, users can construct configurations precisely suited to their needs, which offers flexibility for custom builders and customized settings. Fragola fittings can adapt to diverse automotive applications, from high-performance racing to daily driving setups, with choices that cover a spectrum of requirements.

Applications of Fragola Fittings

Fragola fittings are widely recognized in the automotive racing world for their reliability in critical systems like fuel, oil, and coolant lines. Their accuracy and robustness make them perfect for high-performance automobiles, where safe, leak-proof connections are crucial. Racing teams and performance aficionados may trust these fittings since they can tolerate high temperatures, pressures, and vibrations.

In addition to the automobile sector, fregola fittings are utilized in industrial, maritime, and aviation settings. Stainless steel and anodized aluminium, two corrosion-resistant materials, provide durability and dependability in severe settings, such as high-altitude systems or saltwater.

Custom builders and auto enthusiasts frequently use Fragola fittings for their projects. Fragola’s extensive selection of sizes and combinations enables both professional builders and enthusiasts to develop dependable, high-performance systems for their cars.

Installation and Maintenance Tips for Fragola Fittings

When installing Fragola fittings, it is essential to use the proper tools and take vital safety precautions. Start by ensuring you have the proper wrenches and socket tools that suit the fittings’ scale to avoid detrimental threads. Wearing gloves is suggested to protect your palms from sharp edges and prevent oils or debris from contaminating the fittings. It’s also essential to close the setup vicinity to remove any dust or particles that might interfere with the proper seal.

Overtightening the fittings is a standard setup error. A tight seal is critical, but too much tightening may damage the threads and possibly cause leaks. Furthermore, wrong connections due to the use of the incorrect fitting type for a given utility may cause leakage or system failure. To ensure the suitable type and size are compatible with the hose or gadget, constantly double-check them.

Frequent cleansing and inspection are essential for maintaining Fragola fittings for lengthy-lasting functions. Inspect the fittings for warning signs of wear, corrosion, or leaks in excessive-pressure structures like gasoline or oil strains. Grease and dirt may be removed from fittings by washing them with water and a moderate detergent. Make sure there are not any pollutants present. Look for any harm to the seals, stripped threads, or cracks during the inspection, as these can impair overall performance. You can make sure that your Fragola fittings remain characteristic at their quality for decades by adhering to these pointers.

Comparison with Competitors

The value of Fragola fittings is evident when compared to other brands. Although Fragola fittings may cost more, the investment is well worth it for long-term performance and dependability. Although several rival manufacturers provide less expensive substitutes, their accuracy and durability are frequently lacking. Fragola fittings offer safe, leak-proof connections in high-pressure, high-temperature settings since they are made to tolerate harsh conditions. Fragola guarantees that every fitting will function reliably, even in the most demanding circumstances, for experts and enthusiasts who expect the finest.

When it comes to performance in harsh environments, Fragola is terrific. Their fittings are best for vehicle gas, oil, and cooling structures because they are made to resist high pressures, excessive temperatures, and vibrations. Fragola fittings are manufactured from top-rate substances, including stainless steel and anodized aluminium, giving excellent sturdiness and corrosion resistance. They are, therefore, a first-rate option for disturbing automobile packages, high-overall performance vehicles, and racing.

Fragola’s emphasis on quality and domestic production is one of its main benefits. The meticulous design, testing, and production of each fitting in the United States ensures the finest standards of craftsmanship and dependability. Additionally, Fragola provides a large selection of fittings in different forms, sizes, and angles, enabling modification to meet almost any motorsport or automobile arrangement. Fragola is the preferred call for people who require reliable, superb fittings with a purpose to feature dependably for years because they are determined to have accuracy and advanced performance.

Customer Reviews and Testimonials

Another feature that is often emphasized is how simple it is to install. Because Fragola fittings are made to be easy to use, many customers have commented on how easy and uncomplicated the installation process is. The fittings are perfect for professionals and do-it-yourselfers because they typically need few tools and provide a stable, solid fit. This simplicity of use lowers the possibility of mistakes and guarantees a flawless installation every time.

Fragola fittings are also excellent in practical settings. They are used for high-performance cooling and fuel systems in racing, where they are known to endure harsh circumstances. Even in stressful racing settings, users report fewer leaks or malfunctions. Custom builders also value the range of fittings Fragola provides since it enables customized solutions in unusual car configurations. Fragola fittings are an excellent option for anyone looking for quality and dependability because of their reputation for performance, reliability, and simplicity of use.

Also read: Bulkhead Fittings

Final Words

In the car and excessive-overall performance industries, Fragola fittings are widely known for their exactly built layout, dependability, and longevity. Fragola fittings, constructed entirely within the United States, offer American-made excellence that satisfies the exacting requirements of excessive-overall performance packages, custom builds, and racing. These additives, available in various options from AN fittings to push-lock and PTFE hose fittings, are made from first-rate materials like stainless steel and anodized aluminium, which save you from corrosion and permit them to deal with excessive pressures and temperatures. Fragola fittings, which give a secure, leak-proof connection essential for gas, oil, and coolant lines, are nicely preferred by professionals and do-it-yourself fans due to their easy setup and extensive customization options. Built to excel in difficult conditions, Fragola fittings remain popular for reliability and overall performance in motorsports and beyond, proving a precious choice for car professionals and enthusiasts alike.

For top-quality automotive fittings and unmatched reliability, trust Brain Glower to bring you the best in Fragola Performance Systems.

[…] Also Read: Fragola Fittings […]