Cunado fittings are specialist parts used to join pipes or tubes in a wide range of systems. They are essential for making safe, leak-proof connections that guarantee continuous fluid or gas flow in mechanical, plumbing, and construction systems. These cunado fittings are commonly utilized in heating and cooling systems and pipelines carrying gas, oil, or water, where a great degree of durability and dependability are crucial.

Cunado fittings are made from premium materials like copper, stainless steel, or sturdy plastic and are designed to endure the demands and strains of various industries. From straightforward straight connections to intricate angles and couplings, they come in multiple sizes, styles, and combinations to meet piping requirements.

Types of Cunado Fittings

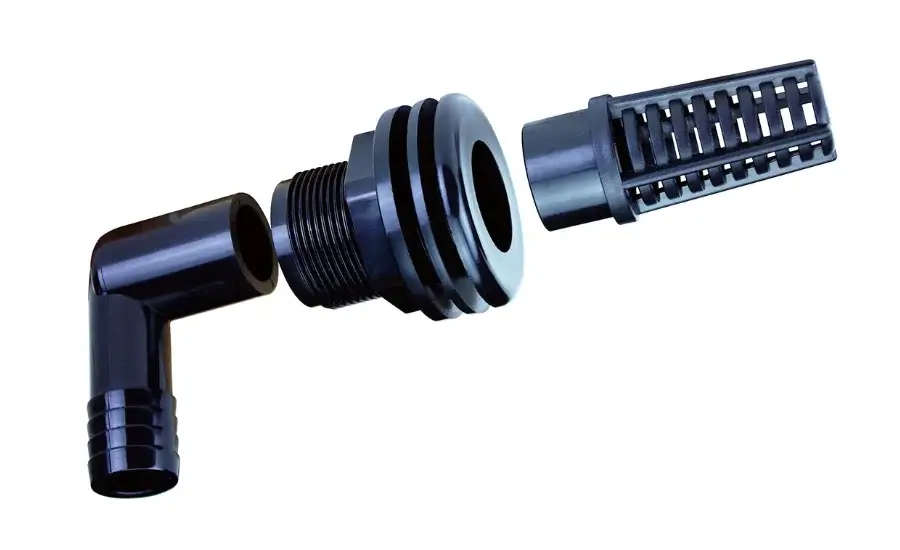

There are various varieties of Cunado fittings, each with a distinct function. An Elbow can redirect a pipeline; 90° and 45° are typical angles. Tees enable the creation of a side connection by branching off a main pipeline. Reducers are used to sign up for pipes of various sizes to ensure seamless transitions among pipes of different diameters. Unions make it easy to detach pipes for protection, while caps seal pipe ends to forestall contamination and leaks.

Cunado fittings are made of special materials that were selected for their sturdiness, corrosion resistance, and ability to withstand pressure. Because of its adaptability and resistance to corrosion, copper is often used in plumbing. Brass offers energy and durability, making it appropriate for excessive-strain systems. Stainless metal is generally utilized in industries like meal processing and HVAC because of its resistance to rust and high temperatures. Plastic fittings are lightweight and chemically resistant, perfect for decrease-pressure systems and clean installations.

Cunado fittings are widely used across various industries. In plumbing, they ensure secure water and gas connections. HVAC systems help maintain efficient airflow and temperature control. Due to their durability under pressure and temperature extremes, the automotive industry uses Cunado fittings in fuel lines, cooling systems, and hydraulics. In chemical and industrial systems, these cunado fittings safely transport liquids and gases, offering reliability and resistance to corrosion.

Advantages of Using Cunado Fittings

Exceptional Durability and Strength: Cunado fittings are fantastically valued for their first-rate sturdiness and strength. Designed to withstand challenging conditions, these cunado fittings can handle excessive stress environments, making them ideal for use in annoying packages. Whether water, gas, or chemical pipelines, Cunado fittings provide reliable and long-lasting connections that are gained without problems falling below pressure. This makes them a pinnacle preference in industries that require dependable performance under challenging occasions, together with plumbing, HVAC, and automobile systems.

Leak-Proof Connections: One of the standout blessings of Cunado fittings is their capability to create leak-proof connections. These cunado fittings are engineered to form tight seals, stopping leaks that might result in pricey harm or hazardous situations. Whether in plumbing, gasoline systems, or business applications, the threat of leaks is minimized, ensuring that structures feature as intended without the fear of fluid or gasoline escaping. This leak resistance is critical for maintaining essential systems protection and performance.

Outstanding Corrosion Resistance: Cunado fittings are regularly crafted from materials that offer incredible corrosion resistance, consisting of copper, brass, or chrome steel. This makes them appropriate for indoor and outdoor programs, even in harsh environments. Whether exposed to moisture, chemical substances, or extreme weather situations, these cunado fittings preserve their integrity and performance. The corrosion resistance enlarges the life of the cunado fittings and reduces the need for frequent replacements or renovation, saving money and time.

Where Are Cunado Fittings Used?

Plumbing and Piping Systems: Cunado fittings are critical in each residential and business plumbing system. They are key in connecting pipes and ensuring secure, leak-unfastened joints. Those cunado fittings help create safe and reliable connections that keep structures functioning efficiently, whether for water delivery lines, fuel systems, or waste management. In plumbing tasks, Cunado fittings are valued for their capacity to face up to strain and save you leaks, making them a cross-to preference for homeowners, contractors, and engineers alike.

Heating and Cooling Systems (HVAC): Cunado fittings are crucial in HVAC structures. These systems depend upon a network of pipes to move air, refrigerants, and water to govern temperature and hold airflow. Cunado fittings ensure that all connections in HVAC structures are stable and leak-proof, which is essential for energy efficiency and the general overall performance of the gadget. Whether in heating gadgets, air conditioning structures, or air flow setups, these cunado fittings help keep proper pressure and save you from any machine disruptions because of leaks.

Industrial and Automotive Applications: Cunado fittings are commonly used in industrial machinery and car structures. They handle fluids in diverse machines, gadgets, and piping networks in industrial settings. From factories to chemical processing flora, Cunado fittings offer steady, long-lasting connections for efficient operation. In the car enterprise, these cunado fittings are regularly determined in fuel traces, hydraulic structures, and cooling systems, wherein they help manipulate fluid glide, save leaks, and ensure the safe and clean operation of cars and machinery.

How Cunado Fittings Work

Cunado fittings eliminate the need for extra sealing materials by establishing safe, leak-proof connections between pipes or tubes. Their unique design ensures a tight, dependable seal using a compression mechanism to hold the pipes in place. The pipe edges are squeezed as the fitting is tightened, stopping leaks and removing the need for gaskets or sealants.

Cleaning the pipe ends to get rid of burrs and debris before installing Cunado fittings will provide a smooth surface for a tight seal. Use the proper equipment, such as a wrench to tighten the fitting and a pipe cutter or reamer to trim and smooth the edges. Ensure the pipes and fitting line up neatly before firmly tightening the fitting without going overboard. Lastly, to ensure the connection is sound, run air, gas, or water through the pipes to check for leaks.

Maintaining Cunado Fittings

Routine inspection and renovation are essential to hold Cunado fittings in pinnacle situations, mainly in high-strain structures wherein put-on and tear can arise more quickly. Regularly test for any signs and symptoms of damage, together with cracks or rust, and search for leaks around the fitting connections. If you notice any uncommon wear, coping with it right away is essential to save you from gadget failures.

Cleaning Cunado fittings frequently is vital to keeping them functioning nicely and avoiding the buildup of minerals, debris, or corrosion. Use a soft material or brush and a mild cleaner that may not harm the best cloth for cleaning. Avoid harsh chemical compounds that could compromise the integrity of the Canadian fittings. Keeping the condo fittings clean enables them to maintain their performance and extends their lifespan, especially in structures exposed to water or chemical substances.

Over time, a few cunado fittings can also wear or break. If this happens, it’s crucial to update them as quickly as possible. A broken fitting can compromise the entire device, leading to leaks or gadget failure. Make sure to apply the proper replacement fitting to meet the device’s requirements and maintain the integrity of your piping community.

Why Choose Cunado Fittings Over Other Options?

Knowing how Cunado fittings stack up against options like compression or push-suit fittings is vital when deciding on Cunado fittings for your undertaking. Compression fittings tighten across the pipe to offer a secure connection, but they may take longer to put in and require more systems or sealants. Conversely, push-healthy fittings are more straightforward but will subsequently be much less resilient or more likely to leak, mainly whilst subjected to high stress.

On the other hand, Cunado fittings offer the correct ratio of dependability to convenience. They offer a sturdy, leak-proof seal, are clean to install, and do not require extra sealing resources. They are perfect for many packages, from commercial structures to plumbing, because their compression mechanism guarantees that pipes remain firmly connected even in high-stress structures. Cunado fittings are a top-notch choice for programs in which long-term staying power is essential.

The affordability of Cunado fittings is a further issue in the decision. Cunado fittings integrate dependability, performance, and simplicity of setup to offer outstanding fees for money, even though opportunity cunado fittings may be much less expensive upfront. Over time, they reduce the need for steeply priced upkeep or replacements by reducing the risk of leaks and harm. Cunado fittings provide reliable performance and fee savings, making them a tremendous investment for small-scale plumbing initiatives and large-scale industrial systems.

Quality Standards and Certifications

Cunado fittings are constructed to exact industry standards, ensuring their dependability and effectiveness in several applications. Internationally recognized standards, including ISO (International Organization for Standardization), ASTM (American Society for Testing and Materials), and CE (Conformité Européenne) designations, are licensed to be met via these cunado fittings. Cunado fittings are assured to have undergone rigorous testing and satisfy the protection and performance requirements required in residential and industrial systems, such as these certificates. You can be confident that you’re using merchandise that meets the highest industry standards when you choose Cunado fittings.

Extensive testing and exceptional control methods are also part of the Cunado fittings production system. Every fitting is checked thoroughly to ensure it satisfies the precise requirements of the packages for which it’s supposed to be shipped. To ensure the Cunado fittings can live to tell the tale of harsh conditions, those checks often contain inspections for corrosion prevention, stress resistance, and durability. By emphasizing first-class manipulation, you can reduce the possibility of mistakes and ensure that every part operates as intended, maintaining your systems’ efficiency and safety.

Where to Buy Cunado Fittings

There are advantages to both online and in-store shopping when making your decision. Convenient online purchasing lets you peruse a large selection of Cunado fittings from the comfort of your own home. It’s simple to compare costs, read user reviews, and occasionally discover better offers. Additionally, many internet merchants save you time by offering home delivery. Make certain you are shopping from official websites focusing on plumbing and commercial components to ensure you are getting genuine, great Cunado fittings.

But when you purchase something in-save, you can look at and sense it to make sure it meets your wishes. You can also talk to knowledgeable staff members to gain expert advice and ensure you choose the right condo fittings for your needs. Buying directly from a local store might provide a more individualized shopping experience, even while in-store options might not have as wide a selection as internet merchants.

Also Read: Fragola Fittings

Final Words

Cunado fittings are essential for creating safe, leak-proof connections in various piping and tubing systems. Made from sturdy materials like copper, stainless steel, and high-strength polymers, they are excellent at withstanding harsh circumstances in multiple industries, including industrial, HVAC, plumbing, and automobiles. Cunado fittings satisfy various pipeline needs with alternatives, including elbows, tees, reducers, and unions, guaranteeing dependable performance in corrosive and high-pressure settings. They create robust, leak-resistant connections without needing additional sealants, which minimizes maintenance and extends system life.

Compared to alternatives, Cunado fittings provide an optimal mix of strength, convenience, and durability, making them a cost-effective choice for residential and industrial systems. Their adherence to strict quality standards like ISO and ASTM highlights their reliability, while the wide range of online and in-store purchasing options ensures accessibility. Cunado fittings are a trusted solution for durable, high-quality connections across many applications.

FAQs

What are Cunado fittings used for?

Cunado fittings are used to create secure, leak-evidence connections in diverse piping systems across industries. They are critical in plumbing, HVAC structures, automobile gasoline and cooling structures, and business pipelines, in which sturdiness and reliability are essential.

What substances are Cunado fittings crafted from?

Cunado fittings are usually crafted from top-notch substances like copper, chrome steel, brass, and durable plastic. Each cloth is selected for its energy, corrosion resistance, and potential to face up to unique pressures and environmental conditions.

Are Cunado fittings leak-proof?

Yes, Cunado fittings are designed to provide leak-proof connections. The cunado fittings use a compression mechanism to create a good, dependable seal without the want for additional sealing substances, minimizing the risk of leaks.

What kinds of Cunado fittings are available?

Cunado fittings come in numerous sorts, inclusive of elbows, tees, reducers, unions, and caps. Each type serves a particular purpose, including redirecting pipes, connecting pipes of different sizes, and sealing pipe ends.

How do I set up Cunado fittings?

To set up Cunado fittings, ensure pipe ends are clean and clean, align the pipes with the right, and use the right gear to tighten securely without over-tightening. This process creates an organization, leak-resistant connection.

How do Cunado fittings examine different fittings?

Cunado fittings provide a dependable balance of durability, ease of setup, and leak resistance compared to compression and push-suit cunado fittings. While other types may require extra equipment or sealants, Cunado fittings are designed to provide stable connections with minimum preservation.

Are Cunado fittings appropriate for excessive-strain programs?

Yes, Cunado fittings are nicely desirable for excessive-pressure applications because of their robust design and substances, making them ideal for use in worrying environments like industrial pipelines and HVAC structures.

Where can I buy Cunado fittings?

Cunado fittings may be purchased online via specialized plumbing and commercial parts outlets or in-keep from hardware and supply stores. Online buying frequently gives a broader choice, while in-save purchases allow for in-character product inspection.

What preservation is needed for Cunado fittings?

Routine inspection is recommended to make sure Cunado fittings continue to be in pinnacle situation. Regularly test for symptoms of damage, corrosion, or leaks, and clean them as needed to prevent particle buildup. Replace any broken fittings right away to hold gadget integrity.

For top-quality Cunado fittings that ensure reliable, leak-proof connections, trust Brain Glower for all your piping needs.