When joining pipes, hoses, or tubing through a solid wall or barrier, bulkhead fittings are specialized connectors made to produce a waterproof seal. They are crucial in establishing safe and impenetrable passageways for liquids to move between various compartments or containers. Bulkhead fittings are particularly significant in applications where fluid containment is essential because of their design, which allows them to tolerate high pressure while successfully preventing leaks.

The primary purpose of a bulkhead fitting is to enable fluid passage through a wall while keeping each side of the barrier separate, ensuring no unintended leakage or contamination occurs. These fittings are often employed in applications where tanks or reservoirs hold liquids and need connections to additional plumbing. They allow fluid flow from one part to another without compromising the integrity of either compartment.

Types of Bulkhead Fittings

Bulkhead fittings come in diverse types and are designed to meet unique desires for connecting pipes and ensuring leak-evidence fluid switches. Here’s a manual to the primary sorts and how they fluctuate in utility:

Threaded Bulkhead Fittings: Threaded bulkhead fittings have characteristic threaded ends that permit pipes or hoses with corresponding threads to be securely screwed into the vicinity. This type gives a reliable seal that can face up to pressure, making it ideal for systems that can require normal disassembly or maintenance, including industrial or plumbing setups. Threaded fittings are generally used for destiny adjustments or maintenance, as the threaded layout allows for smooth removal and reinstallation.

Slip Bulkhead Fittings: Slip bulkhead fittings have a clean, non-threaded design, permitting pipes to slide into location before being sealed with an adhesive or solvent. These fittings are frequently used in programs requiring an everlasting, durable connection. Slip bulkhead fittings are especially famous in aquariums, water tanks, and irrigation systems, as they offer a smooth, continuous route for water glide with minimal danger of leaks as soon as the adhesive sets.

Compression Bulkhead Fittings: Compression bulkhead fittings use an aggregate of nuts and rubber washers to create a tight, watertight seal across the pipe. They are handy for skinny-walled or flexible tubing packages, where threading or slip connections won’t paint as efficaciously. Compression fittings offer flexibility and ease of setup, making them a top desire in plumbing structures, water remedy plants, and numerous styles of devices wherein short setup and reliable sealing are essential.

Flanged Bulkhead Fittings: Flanged bulkhead fittings have a flange, or collar, on one stop that allows the fitting to be bolted to a surface, such as a tank or wall. This layout presents added balance and safety, in particular in packages involving large pipes or higher pressures. Flanged fittings are regularly used in commercial settings, where strong performance is essential. The flange facilitates the distribution of pressure lightly across the becoming, lowering strain on the tank or wall and minimizing the risk of leaks or cracks.

Each type of bulkhead fitting is crafted to meet specific requirements in fluid transfer, ensuring that no matter the application, there’s an option that balances strength, convenience, and leak prevention. By selecting the right type for the job, you can ensure efficient and secure connections tailored to your system’s demands.

Materials Used in Bulkhead Fittings

Bulkhead fittings come in various materials, every perfect for particular environments and applications:

PVC (Polyvinyl Chloride): PVC is lightweight, less luxurious, and highly resistant to corrosion, making it perfect for low- to slight-pressure systems like residential plumbing, aquariums, and water tanks. However, it’s less appropriate for high-temperature or high-pressure environments.

ABS (Acrylonitrile Butadiene Styrene): ABS shares PVC’s corrosion resistance; however, it is extra durable and impact-resistant, making it popular in water remedies and plumbing. However, it could warp beneath high heat, so it’s quality for medium-obligation, room-temperature programs.

Brass: Brass balances power and corrosion resistance for freshwater applications, correctly handling moderate pressure and temperature. It may additionally corrode in saltwater or acidic environments, so it’s best appropriate for standard residential or business plumbing.

Stainless Steel: Chrome steel is unbeatable for high-power, heavy-obligation, or corrosive packages. It resists rust, high temperatures, and stress, making it perfect for commercial, marine, or chemical environments. Although more expensive, its sturdiness and reliability justify the investment.

Choosing the Right Material

Corrosive or Saltwater: Opt for stainless steel for long-lasting corrosion resistance.

Underwater Applications: PVC or ABS work well for low-budget projects with minimal heat exposure.

High Temperature/Pressure: Stainless steel can withstand demanding conditions.

Selecting the appropriate material ensures reliable, long-lasting performance tailored to your environment.

How Bulkhead Fittings Work

Bulkhead fittings allow Pipes or tubes to bypass through partitions, tanks, or containers whilst preserving a watertight or hermetic seal. The primary function of a bulkhead fitting is to create a steady connection that stops leaks, ensuring that beverages or gases stay contained.

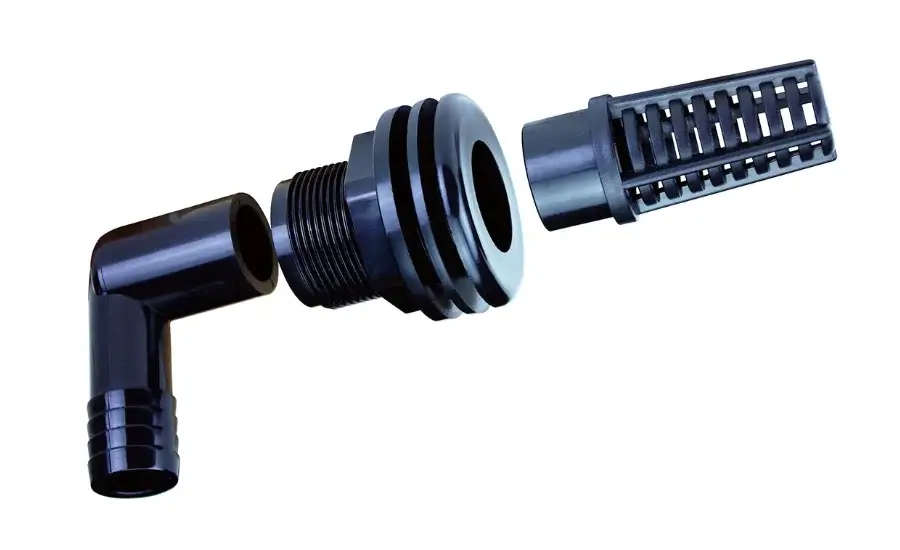

These fittings include a threaded or slip-fashion connection that passes through an opening, with a seal on every aspect of the wall. The fitting compresses against the surface when tightened to create a reliable barrier. Standard sealing methods include:

O-Rings: These rubber or silicone rings sit around the fitting and compress as the fitting tightens, forming a flexible and durable seal ideal for various pressures.

Gaskets: Flat or ring-shaped gaskets fit between surfaces to create a solid seal, especially for uneven surfaces or higher-pressure applications.

Using these sealing elements, bulkhead fittings are essential for applications requiring controlled fluid or gas flow without the risk of leaks, such as in plumbing systems, tanks, and industrial containers.

Step-by-Step Guide For Installation of Bulkhead Fittings

To install a bulkhead fitting, start by gathering tools and materials, such as a drill, drill bit matching the fitting’s size, wrench, sealant, and the bulkhead fitting itself, along with an O-ring or gasket. Then, using the chosen bit, drill a hole in the container wall, ensuring the fit is snug, and the edges are smooth to prevent leaks.

As advised, the fitting should be inserted through the hole with the gasket or O-ring inside or outside. Using a wrench, carefully tighten and compress the seal after threading the fitting’s nut onto the other side. To avoid damaging the fitting, take care not to overtighten.

Make sure the hole is the right size, and consider applying a little sealant around the fitting for a snug fit. Proper installation will produce a reliable, waterproof seal for various tank and pipe applications.

Common Applications of Bulkhead Fittings

Bulkhead fittings are essential in various sectors because they provide dependable, leak-proof connections for tanks, pipes, and containers. A closer look at the industries that typically employ these fittings and how they enhance each application is provided below:

- Plumbing and Irrigation: In plumbing and irrigation systems, bulkhead fittings are essential for passing water through partitions, tanks, and obstacles. Considering efficient water float, they ensure a stable, leak-unfastened connection between pipes and bins. Bulkhead fittings are generally used in rainwater harvesting, water filtration systems, and irrigation structures, where reliable, long-lasting connections are essential to maintain proper water management.

- Aquariums and Fish Tanks: Bulkhead fittings are necessary for aquarium setups, specifically for connecting filtration systems, overflows, and pumps to the tank. These fittings create tight seals, preventing leaks and allowing controlled water drift. They are mainly treasured in massive or saltwater aquariums, where preserving solid water tiers and green filtration is crucial to assisting aquatic lifestyles.

- Agricultural Tanks and Storage Containers: Bulkhead fittings are utilized in garage containers and tanks in agriculture to transfer chemicals, fertilizer, and water. They ensure that contents are neatly contained by offering a secure, reliable connection for pipes or hoses. Bulkhead fittings are very helpful in large-scale farming, where green fluid control is essential for irrigation and agricultural product distribution.

- Chemical and Industrial Processing: Bulkhead fittings move liquids or gases between different gear or compartments in chemical and industrial processing plants. They keep systems sealed to stop contamination and leakage, which is crucial when working with dangerous materials. Because of their strength, resistance to corrosion, and capacity to tolerate high temperatures, bulkhead fittings made of stainless steel or specialty plastic are frequently used in industrial and chemical settings.

Bulkhead Fittings vs. Other Fittings

Bulkhead fittings are frequently compared to other types of fittings like unions, couplings, and adapters. While most of these fittings serve to attach or seal pipes and tubing, bulkhead fittings offer wonderful benefits in certain packages, particularly with regard to developing leak-proof, steady connections via walls, tanks, or bins.

Unions: Unions are fittings designed to connect two pipes or tubes in a way that permits clean disassembly for upkeep or repair. They include two give-up fittings and a relevant nut that holds them collectively. While unions are splendid for systems that require frequent disconnections, they do now not provide an equal level of sealing for partitions or tanks as bulkhead fittings. Bulkhead fittings are favored, whilst a secure, everlasting seal is needed among pipes and walls, especially in excessive stress or underwater environments.

Couplings: Two pipes of the same length may be joined via couplings, typically without the need for threading or more fittings. They are regularly used in plumbing and are clean to install. However, while flowing through a wall or barrier, they lack the Waterproof seal that bulkhead fittings provide. Because of their sealed nature, bulkhead fittings are best for structures where stopping leaks at the point of entrance or exit is essential.

Adapters: Adapters are fittings designed to enroll in pipes of different sizes or kinds (e.g., PVC to brass). While adapters are essential for converting between incompatible pipe structures, they do not offer the same stage of durability or sealing skills as bulkhead fittings in wall or container connections. Bulkhead fittings excel in applications where a tight, reliable seal is essential to prevent leaks in tanks or pressurized systems.

Why Bulkhead Fittings Are Preferred

Bulkhead fittings are frequently desired in applications requiring a sturdy, reliable seal between a pipe and a wall, tank, or field. Their layout lets them provide advanced leak prevention, critical in industries like aquariums, chemical processing, and irrigation. The capability to hold a tight seal beneath pressure and environmental stress makes bulkhead fittings especially suitable for long-term use, ensuring system integrity through the years.

In contrast to unions, couplings, and adapters, bulkhead fittings offer the advantage of versatility, specifically in situations where connections want to skip via limitations or packing containers. Their sealing performance, ease of installation, and capacity to deal with diverse pressures make them the go-to choice for plenty of fluid-related programs.

Troubleshooting Common Issues with Bulkhead Fittings

Although bulkhead fittings are long-lasting, problems may arise in the future. Regularly inspect the gasket or O-ring for damage and replace it to stop leaks. Ensure the fitting is securely attached and not overtightened, which may harm the seal. For added protection, use a waterproof sealant around the fitting.

Wear and corrosion might occur, particularly in extreme conditions. As soon as rust is detected, replace the fitting. Don’t overtighten; check the tension occasionally and adjust as needed. Check for damage or cracks, and if necessary, replace the fitting.

Turn off the water supply before performing routine fitting inspections. As necessary, repair worn fittings and check for leaks. Before installing a new one, clean the area and tighten it carefully to prevent leaks. By keeping your bulkhead fittings maintained, you can guarantee their lifetime and dependability.

Maintenance and Care for Bulkhead Fittings

Use a gentle cloth and mild cleaner to clean your bulkhead fittings regularly to prolong their lifespan. To prevent corrosion in fittings subjected to hostile environments, rinse them of any chemicals or seawater. Avoid abrasive equipment and aggressive chemical compounds that can damage seals.

Watch out for wear indicators such as corrosion, cracks, or unfastened fittings. As soon as you notice any problems, replace the fitting. Periodically check the tightness, but avoid overtightening, as this may harm the seal.

Examine your fittings every six to twelve months or more frequently if they are subjected to extreme conditions. Frequent maintenance will help them last longer and continue to operate dependably and without leaks.

Safety and Compliance Considerations

Safety is crucial when using bulkhead fittings, especially in high-pressure applications. Ensure fittings are rated for the specific pressure and that seals are intact to prevent leaks or failures.

For applications involving food, water, or pharmaceuticals, ensure fittings have relevant certifications like NSF or FDA approval to guarantee they are safe and won’t contaminate the products.

Comply with local regulations and industry guidelines for chemical or food processing. Regular inspections and proper installation are key to meeting safety standards and avoiding risks.

Expert Tips and Recommendations

When deciding on bulkhead fittings, choosing the proper fabric is essential based totally on your wishes. For popular programs, PVC and ABS are top options, while stainless steel or brass are better suited for high-stress or corrosive environments. Always check whether the material is rated for the pressure or chemical compounds it’s going to encounter.

During setup, ensure the hole size is accurate and the fitting is securely tightened. However, avoid overtightening, as it may harm the seal. Use an extremely good gasket or O-ring and look at it frequently for wear. Using sealant across the fitting can offer more excellent protection in high-stress structures.

Regular upkeep is crucial for lengthy-term performance. Inspect fittings for signs and symptoms of corrosion, cracking, or loosening, and update any worn additives immediately. Be conscious of the fabric’s compatibility with the fluids or gases used, as a few materials may degrade under harsh conditions.

Always consult the producer’s specifications and enterprise requirements, like those from NSF or ASTM, to ensure the fittings are safe and compliant. Following these suggestions will help preserve the integrity and reliability of your bulkhead fittings.

Sum Up

Bulkhead fittings are essential for creating secure, leak-proof connections in various applications, including plumbing, aquariums, industrial processes, and irrigation systems. These fittings maintain fluid integrity and prevent contamination or leakage by ensuring a tight seal between pipes, hoses, or tubing and walls, tanks, or barriers. Different types, such as threaded, slip, compression, and flanged bulkhead fittings, cater to specific needs, offering flexibility for various environments. Materials like PVC, ABS, brass, and stainless steel are selected based on the application’s pressure, temperature, and corrosion resistance requirements. Proper installation, regular maintenance, and material selection ensure long-lasting, reliable performance. Regular inspections, cleaning, and timely replacements of worn parts are crucial for maintaining system efficiency and avoiding costly repairs. Bulkhead fittings are pivotal in industries where fluid management and containment are critical, offering a robust solution for seamless fluid transfer across barriers.

For seamless fluid transfer and reliable leak-proof connections, trust Brain Glower for all your bulkhead fitting needs.

[…] Fittings are perfect for fuel, oil, and coolant lines in performance vehicles because of their standardized dimensions and thread types, which provide broad compatibility across various applications. They are typically made of high-grade aluminium and frequently have an anodized surface that increases strength and prevents corrosion. Fragola’s AN fittings meet these requirements, guaranteeing accurate thread engagement, tight seals, and compatibility with high-performance systems. Because of their design, they are particularly well-liked by car enthusiasts who need reliable, long-lasting connections. […]